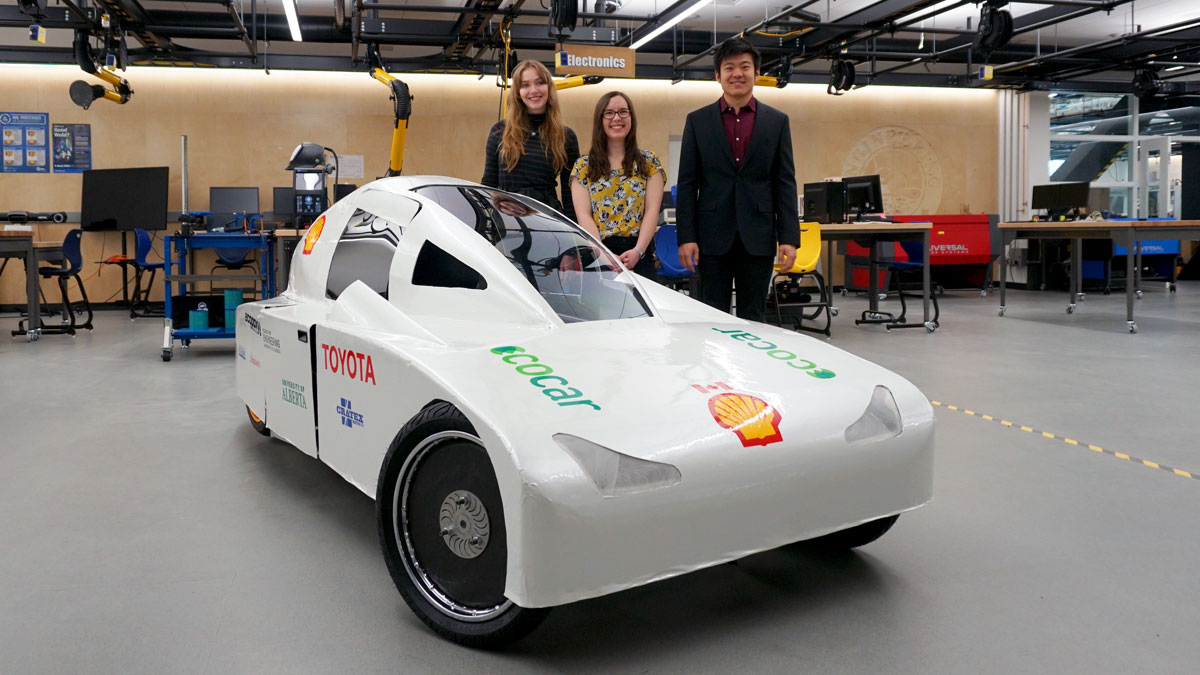

Meet Kate, the new hydrogen fuel-cell powered car designed and built by the UAlberta EcoCar Team. In April, the team is bringing Kate to the Shell Eco-marathon Americas competition in Sonoma, California. There, along with teams from North and South America, the students will put Kate to the energy efficiency test on the road.

(Edmonton) An Engineering at Alberta student team has unveiled a new zero-emissions car they designed and built over the past year, and are ready to test their work against student teams from around the world.

With electric cars taking up more and more space on showroom floors and our roads, it may come as a surprise that undergraduate students are designing and building hydrogen fuel cell vehicles.

"Some of us are right out of high school," said UAlberta EcoCar project manager Willow Dew, a fourth-year chemical engineering student who initially joined the team during her first year of studies.

"A significant number of first-year students join and it's beneficial to them and the team," she said. "You find out that you can contribute more than you thought, and on this team there's a really strong culture of mentorship and helping each other."

In April, the team will bring its new hydrogen fuel cell powered car, which they've named Kate, to the Shell Eco-marathon Americas competition in Sonoma, California. There, along with teams from North and South America, the students will put Kate to the energy efficiency test on the road.

Each team's vehicle heads out on a 10-km course cruising at an average speed of about 24 km/h. The team that uses the least amount of energy wins.

"Last year with our prototype vehicle Sofie, we achieved the equivalent of almost 2,000 miles per gallon," said Dew. Sofie, a long, sleek, three-wheeled vehicle resembling a torpedo on wheels, competed in the prototype-hydrogen category, reserved for experimental vehicles.

This year, the team is entering the Urban Concept category. In this category, vehicles need to look and operate like something you'd see on a showroom floor. The Urban Concept vehicles need to have signal lights, mirrors, brake lights, windshield wipers-components that make it safe to drive on the street.

The UAlberta team's goal is not necessarily to win, but rather to provide students with the best learning opportunities possible. Dew says that starting from a blank sheet of paper, working through the design process, then actually building and competition with the car provides team members with a full spectrum of challenges and opportunities.

And sometimes, the best way to learn means intentionally doing things the hard way.

EcoCar fuel cell team lead Erin Whitby says that other teams buy fuel cells with integrated electrical systems, but the Engineering at Alberta team buys a product that is really "just a stack of membranes and graphite plates."

"A fuel cell is a stack of materials that facilitate a chemical reaction that happens across these membranes," Whitby said. "But we do the rest of the work, supplying it with hydrogen, putting a load across it, and designing and building the control system that allows it to either charge the super capacitors or run the motor."

Ultimately, the team wants to be the first in the competition to design and build its own fuel cells from scratch-and to produce its own hydrogen through renewable energy sources. They hope the work they have been putting toward these aims this year will pay off at future competitions.

Dew and Whitby say being on the team has enriched their engineering education by exposing them to the expertise of various engineering disciplines and giving them hands-on work that strengthens their design and technical skills.

"This gives us design experience that we don't get to see in the classroom," said Whitby, who's studying electrical engineering. "We're designing and building printed circuit boards from scratch-which makes up the vehicle's whole electrical system."

Dew says working in an interdisciplinary team gives students experiences that more accurately mirroring professional engineering work.

Her previous roles on the team have been in the research and development group, and the fuel cell team, and Dew says she learns something new from team members.

"My classes teach me about chemical reactions, and process engineering, and industrial design, and analyzing big reactors," she said. "When I'm working with people from other disciplines like mechanical engineering, I'm learning about aerodynamics and gear ratios, and other things I wouldn't otherwise get a chance to learn about."

But the motivation for getting involved never strays far from wanting to have an impact on the world.

"We're making progress on something that will make a difference," said Whitby. "EcoCar has a valuable outcome."

"It's a project that is very relevant," added Dew. "It's problem solving that has meaning and implications for the future."