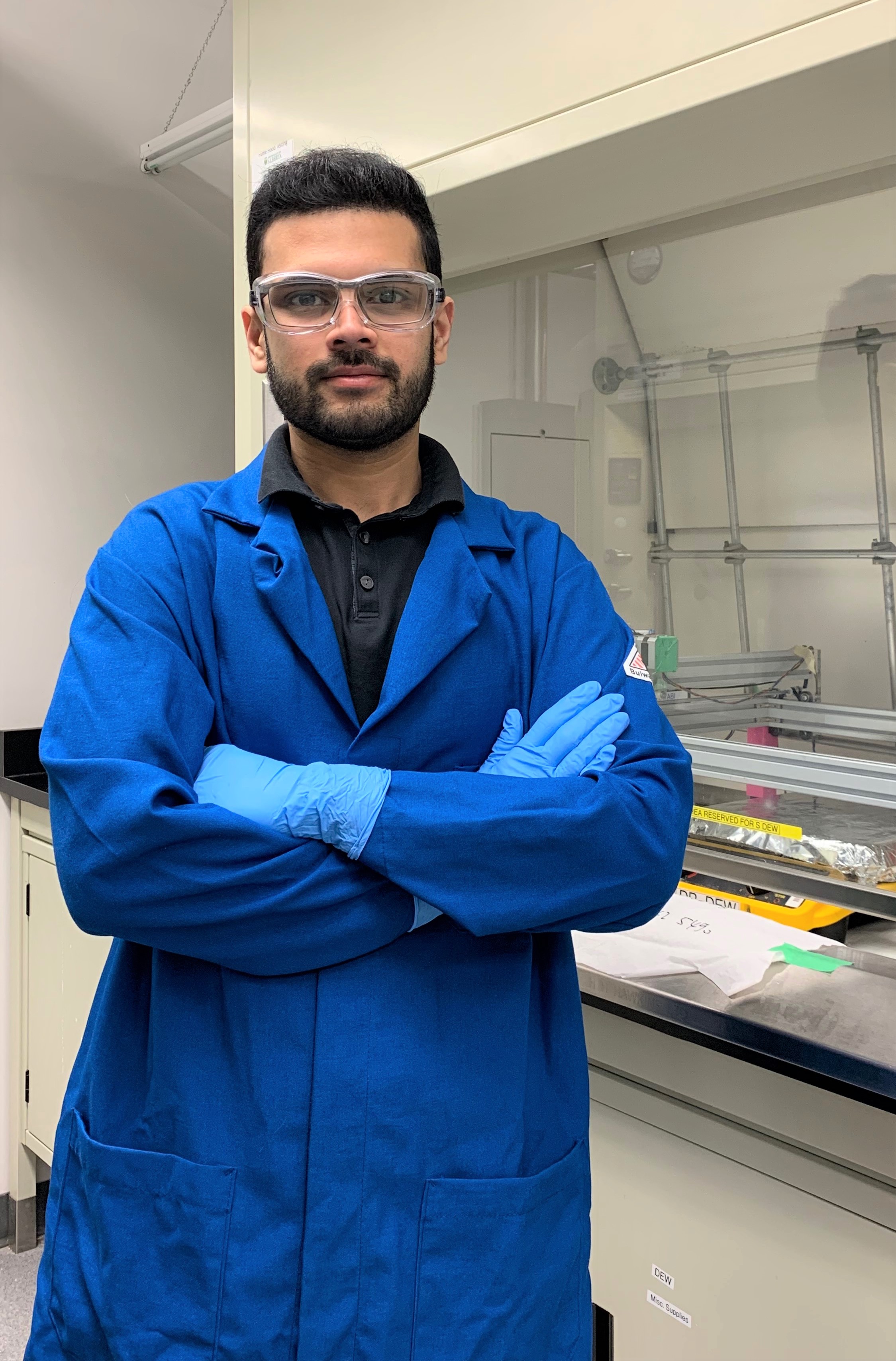

Faculty of Engineering Safety Advisor Syed Biyabani has had a tremendous impact on the faculty's environment, health and safety unit.

(Edmonton) North American Safety and Health (NAOSH) week was first launched in June 1997, marked by an agreement between Canada, the United States, and Mexico. The goal of Safety and Health week is to focus employers, employees, and the public on the importance of preventing injury and illness in the workplace, at home, and in the community.

The Faculty of Engineering's top priority is the safety and well-being of our students, staff, and faculty members. With our leading-edge technology and research, we are able to teach and conduct several safety protocols, hands-on workshops and laboratories throughout our department. Our safety culture involves all levels of leadership involved in the safety committee.

Faculty of Engineering Safety Advisor Syed Biyabani has had a tremendous impact on the faculty's environment, health and safety unit. We spoke to him about building and living a culture of safety.

Q: Can you tell us a bit about yourself, and what your role here at the Faculty of Engineering is?

A: I'm a mechanical engineer with a background in engineering safety and risk management. I've worked for Environment, Health and Safety for a little over two years. Then I got hired on by the Faculty of Engineering's David and Joan Lynch School of Engineering Safety and Risk Management, and worked there for over a year. In January, I started working with the facilities and safety team for the Office of the Dean for Engineering.

My role is to look into inspections, incident investigations, staff safety training, contractor safety management and review, research safety review, and to manage the health and safety management system for engineering. I also look into our facilities safety and needs. For example, if you are installing new equipment into our spaces, we would review its safe operation that would take into account everything around equipment safety, as well the operators' safety.

Q: What are the current statistics for the Faculty of Engineering this year so far? In terms of safety procedures and accidents?

A: This year has been really good. We haven't had any major incidents. Nothing that has been a reportable incident. We've had our minor incidents, near misses, but we have been doing pretty well. I think this is due to our extensive safety trainings and leadership involvement.

For stats, we have done over 1,100 self-inspections alone in 2018, which is 1,100 inspections done throughout the faculty. We have about 350-500 lab spaces that go through inspections on variable frequencies based on their hazards. These inspections help us to determine working conditions and commitment to safety from individual labs.

Q: How do you stay up to date with current policies, regulations and industrial procedures?

A: This position comes with a lot of learning and responsibilities. Generally, learning the codes (the Alberta Fire Codes, Alberta Building Code, and the Occupational Health and Safety (OHS) code) is an ongoing process. You keep learning new stuff every day. It's basically based on the situation that you face, the kind of recommendations that are required. You face different situations every day. I would say learning keeps on going every day. As it is crucial, and to review our lab floor plans, research projects, the kind of safety equipment needed to store certain things, and also to help workers understand these hazards.

Q: Can you give us a walkthrough of how you do inspections?

A: For inspections, what we do is go through a 10-section inspection form which goes through everything from housekeeping all the way to radiation, laser, chemicals, emergency management and corrective actions. We are also in the process of creating an in-house database which will reduce inspection time and hopefully increase our inspections from 1,100 to probably 1,500 to 2,000 a year. For an inspection to be thorough, I go through the type of research being conducted in a space to understand what needs to be expected, then I meet with the lab manager or the principal investigator, conduct an inspection with them and help them understand what their hazards are based on their research and equipment in their space.

Q: Can you go more in-depth with the faculty's hazard management?

A:Part of my role is to implement the Faculty for Engineering's health and safety management system. We have a 10-element program that helps us guide our labs, our work spaces, and all our off-campus sites, basically anyone that works for the Faculty of Engineering, to work in a risk-mitigated manner. This includes everything from the lab door hazard signs all the way to hazard assessments, SOPs, safe work procedures, field-level risk assessments, emergency management, training, etc.

Q: Is there any resources students or staff can refer to when it comes to hazard management?

A: We have an app called E Compliance Hazard Assessment Web Application. It's available both as a mobile app on Apple and Google app store, and as a website on ecompliance.com. The application comes pre-populated with hazard information and templates. This makes doing hazard assessments user friendly and easy. Ideally before ever starting work, every student or staff member should go through a hazard assessment and review it with their supervisor.

Q: Can you talk about what the David and Joan Lynch School of Engineering Safety and Risk Management is?

A: University of Alberta is the only university in Canada with a program of its kind. The school provides courses that are well structured and very realistic to the application of engineering safety and risk management within industries and institutions. This area of expertise is rapidly evolving, and by having a school dedicated to just safety management, this opens doors for opportunities and continuous education on reduction of risk exposure to people, the environment, facilities/assets and business productivity.