Mechanical Engineering professors, André McDonald and Arman Hemmati, have each been awarded the Alberta Innovates Climate Change Innovation and Technology Framework (CCITF) grant for $100, 000. The CCITF program is designed to support and enhance the development of clean innovations, to improve Alberta's ability to reduce greenhouse gas (GHGs) emissions, promote economic diversification, and transition to a lower carbon economic system.

Professor McDonald will use his CCITF grant to develop and test functional coatings for heat exchangers that will be placed inside exhaust flues and gas stacks. Placing the specially-coated exchangers in flues and stacks will turn otherwise wasted heat energy into clean electricity.

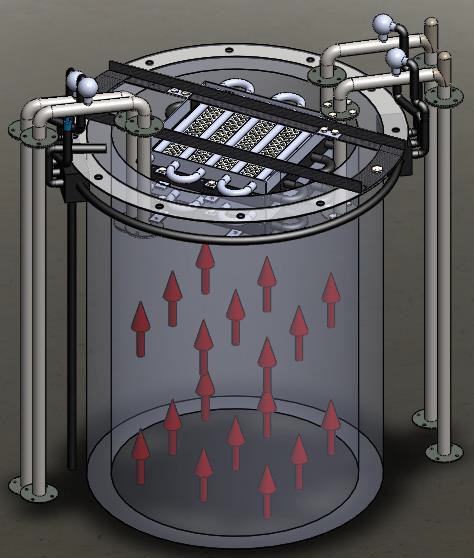

Render of assembled heat exchanger mounted on flare stack, hot gases flow as indicated by red arrows (image credit: Rezaey, University of Toronto)

"Most coatings protect surfaces like those in pipes and flues against wear and corrosion. They're passive," explains McDonald. "But we can make smart coatings that are also functional."

Smart coatings provide protection for pipe against wear and corrosion and also provide some benefit, such as serving as sensors. For this project, Dr. McDonald will use a coating that captures and conducts heat. The coating will be applied to a heat exchanger that will be placed inside flare stacks and boiler flue gas stacks at oil and gas processing plants. The heat exchangers will capture heat that is typically simply emitted as waste and the coating will conduct the heat energy to a turbine to generate electricity.

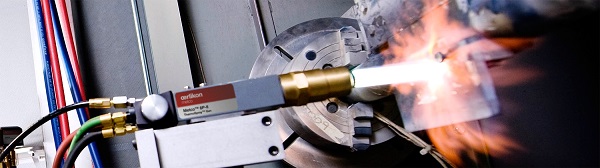

Flame spray setup at the University of Alberta Advanced Heat Transfer and Surface Technologies Laboratory

Jerry Han is a Master of Science student working with Dr. McDonald on the project.

"We're mitigating the effects of climate change in two ways," he explains. "We're reducing the amount of heat that is released into the environment. And we're generating energy from a by-product of oil and gas production."

The work is a collaboration with Professor Sanjeev Chandra at the University of Toronto, who has developed the prototype heat exchanger that McDonald and Han will test. Tests will ensure the coatings perform as well as expected and will determine problems that need to be addressed, such as cracking or corrosion issues. Testing will begin in house in the Mechanical Engineering building before moving to sites with Imperial Oil.

Han is excited to be working on such novel clean energy technology. "It's not a traditional clean energy technology, like solar panels. That's what's so great."

Professor Hemmati will use his CCITF grant to develop a proof of concept for more efficient pipes to be used in the oil industry.

"As a liquid flows through a pipe, the vortex structures take common shapes or patterns," he explains. "We want to develop a pipe that can introduce certain flow patterns, to reinforce the vortex structures with the highest energy and reduce the ones with the lowest energy."

Building pipes that contain high energy vortex structures will reduce interactions between the liquid and the pipe wall, which will in turn reduce erosion and corrosion. In cross-section, the high energy vortex structures in a pipe look like a notched circle, or like a gear. Pipes that reinforce high energy vortex flows will decrease the energy required to pump liquid through, and reduce erosion and corrosion, leaks and spills.

Hemmati was introduced to this idea during his postdoctoral fellowship at Princeton University, where the original design idea was developed by Professor Smits' team.

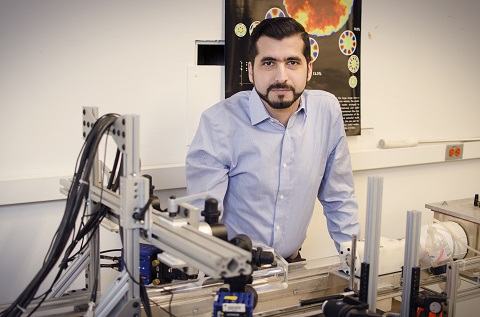

Dr. Hemmati with the prototype at Princeton University. The poster behind him shows the vortex structures that his prototype will optimize.

"We tested the concept with water at Princeton. I'm bringing the idea to Alberta's oil sands operations."

Although Hemmati has tested the technology with water, he will use his CCITF grant to develop and test the idea for high viscous flows, such as bitumen. Professor Hemmati is recruiting one graduate student for the project. The student will run computational simulations to optimize the design and ensure the concept works. The project continues to be a collaboration with Princeton University as the team continues to optimize the design of this technology for various industrial applications. . Hemmati anticipates travelling to Princeton with the graduate student on the project.

"The CCITF framework supports research and technology development that will mitigate GHGs. We're just building on Alberta's strengths," says McDonald.