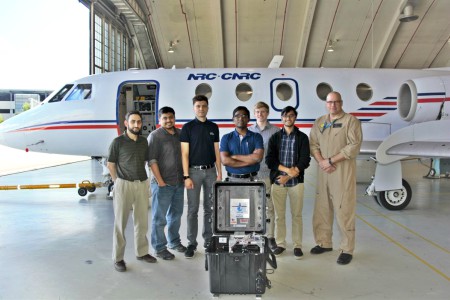

Left to Right: Shahrukh Alvi (NRC), Farhad Ismial, Aleksey Baldygin, Prashant Waghamre, Ryan Baily, Muhammed Khan, and Duff Gowanlock (NRC).

Also known as the “puke plane” the aircraft is used to perform parabolic manoeuvres to simulate microgravity conditions so that researchers can run experiments to learn about microgravity and zero gravity conditions.

The team had won a spot on the plan in a national competition called Students for the Exploration and Development of Space (SEDS-Canada). Their goal was to test the formation and crystallization of droplets from a 3D printer in zero gravity conditions.

How do droplets form in space?

While much is known about the formation of droplets here on Earth, little is known about how the process would work in zero gravity conditions. Learning how 3D printing works in micro- and zero-gravity conditions is a priority for the Canadian Space Agency. Having 3D printers aboard the International Space Station, for example, will make it easier to repair the station or perform work in the station.

Five members of team iSSELab were in Ottawa for the tests: Waghmare, who is a professor in the Department of Mechanical Engineering and the team’s supervisor; Aleksey Baldygin, the iSSELab laboratory supervisor; and recent mechanical engineering graduates Ryan Baily, Muhammed Khan and Farhad Ismal.

Baily and Ismail, who is now working towards his PhD, flew aboard the Falcon 20 with two members of a team from the University of Toronto. Each team was accompanied by a technical advisor from the National Research Council. Bailey was responsible for running the experiments and says all the students were affected by motion sickness but the NRC advisors, who are well practiced at parabolic flight manoeuvres, were not.

The flight consisted of a climb from 11,000 feet to 20,000 feet at a 40 degree angle, creating a force of 2G. At the top of the ascent, the students experience near-zero gravity for just over 20 seconds until the plane began its descent, which also created two G forces.

A physical flight!

During the flight, Baily was responsible for controlling six pieces of software that controlled five pieces of equipment.

“It was hard on my body,” he says. “I had to begin recording right at the beginning of the 2G pull. Then right before micro-gravity I had to form the droplet and then stop the recording at the end of the 2G descent. During the level flight between climbs I had to move the dosing unit and the stages for the next run.”

Not only was Baily fighting against 2G forces for this work, he was also, of course, strapped into his seat and working on a computer he had to stretch to reach.

After the flight the team had a few days in Ottawa to analyze data. They found that the zero gravity did affect the formation of droplets extruded by a 3D printer. The droplets formed in micro-gravity had a lower contact angle than those deposited on Earth. That is, they were a bit rounder on the plate. What’s more, the pointy tip that forms at the top of droplets was shaped differently, at a lower angle, which means that the droplet was a bit pointier.

Now that the team has experience and has some results, they want to do it again.

Wanted: undergraduate researchers

“We’re happy that we have a functional and proven system and a trained operator,” says Baldygin,the iSSELab laboratory supervisor. “We only did seven runs and we’d like to do more.”

“This success was made possible by SEDS, the Flight Research Laboratory, the NRC and the CSA,” said Waghmare. “But it is only a baby step in a very large challenge.”

The team is in talks with the Canadian Space Agency about arranging future flights. In the meantime they’re working to consolidate the six software programs into a single program so that the operators have less to manage during future flights.

The team’s week in Ottawa ended with a closing ceremony where they and the U of T team presented their findings. There too, the team was met with a once-in-a-lifetime chance as they were seated with former Canadian astronaut, Robert Thirsk.

Now that they’re back home, members of the team are entirely focused on the work ahead and making sure they get to take another ride on that roller-coaster.

And they’re looking for others to join the ride.

Hands-on engineering experience

“We are seeking talented, bright, motivated undergraduate students to get involved in this research,” said Waghmare. “This is the best opportunity to get hands-on experience for microgravity experiments and the challenges associated with such experiments. It might be someone’s only chance to experience microgravity.”

Waghmare, was impressed by the effort of SEDS-Canada, the CSA and NRC scientists and engineers. “This is the first time this event was organized and it happened because of the tremendous efforts from SEDS group. NRC scientists and engineering were with us for entire week to make sure experiment works. And the CSA supported this flight campaign,” he said.

The project was also supported by three different companies—KRUSS GmbH, Zaber Technology, and Engineering Beyond, as well as funding from Faculty of Engineering.

“I am so grateful to our collaborators and sponsors,” he said.