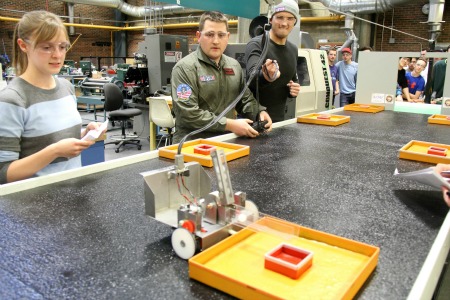

It's one of the best exams ever-members of Team Top Gun are focused on their vehicle's performance.

(Edmonton) Second-year students studying mechanical engineering can expect to have their biggest homework assignment ever broadcast on the evening news.

Students in Mechanical Design I (MecE 260) are split into teams of four or five, given a limited supply of materials and tools and have one semester to design and build a robotic vehicle capable of executing specific skills. Teams race their vehicles for the final exam. Winners are scored based on speed and the completion of a set of tasks. The event always draws a crowd. And the media.

MecE 260 takes learning beyond the books and provides students an opportunity, early in their degrees, to work in a 'hands-on' way with tools and apply what they're learning in class. It's an important step in an engineer's education to learn how the world actually works, not just how things should work in theory.

"The design challenge is an opportunity for students to use their ingenuity and come up with their own solutions to a given problem," says Department of Mechanical Engineering Chair, Brian Fleck. "We are developing Alberta's new work force and so problem-solving skills are important in an economy that has begun to diversify and will continue to diversify."

Most MecE 260 teams learned the hard way that, although a design works on paper, the real test comes with the actual building.

"The challenge is a chance, early on, to learn the practical side of design and manufacturing. That's really important for going into industry but they can also apply what they learn to the courses they take later on," says one of the course teaching assistants, Nathan Maeda.

Members of the winning team spent longer designing their vehicle than they spent building it precisely because their first design just didn't work. "Things don't go as planned," says Jacob Bellerose. "We learned to 'stay calm when things go wrong.'"

For some teams the numbers and equations weren't as helpful as the trial runs.

"We designed our vehicle to run at .6 m/s. But it's hard to imagine what that looks like," says Taylor Brodziak. "Once we had the motor in we realized it was too fast. We had to replace the motor and slow it down."

Beyond acquiring new skills and working with materials and tools, students also learned how to manage a long-term group project with a lot of trouble shooting. "You really need to ask a lot of questions and communicate well," says Enrique Marroquin, project manager for the second-place team. "I also paid a lot of attention to our supply of materials. It was like a budget."

"Our students are getting these really diverse skills that they can contribute to the industries that need them," says Fleck. "We're training our students to improve Alberta's competitive advantage."

"I have a real sense of accomplishment," says James Carson. "Yeah, but I'm also kind of sad that it's over," adds a classmate.

Everyone agrees.