New University of Alberta research is making 3D printed food safer to eat — using the machine itself.

Experiments showed that the heating element inside a 3D food printer, already used to keep edible paste pliable enough to form different shapes, can also kill Salmonella. The harmful bacteria are responsible for five per cent of food-borne illness, 24 per cent of related hospitalizations and 16 per cent of related deaths in Canada every year.

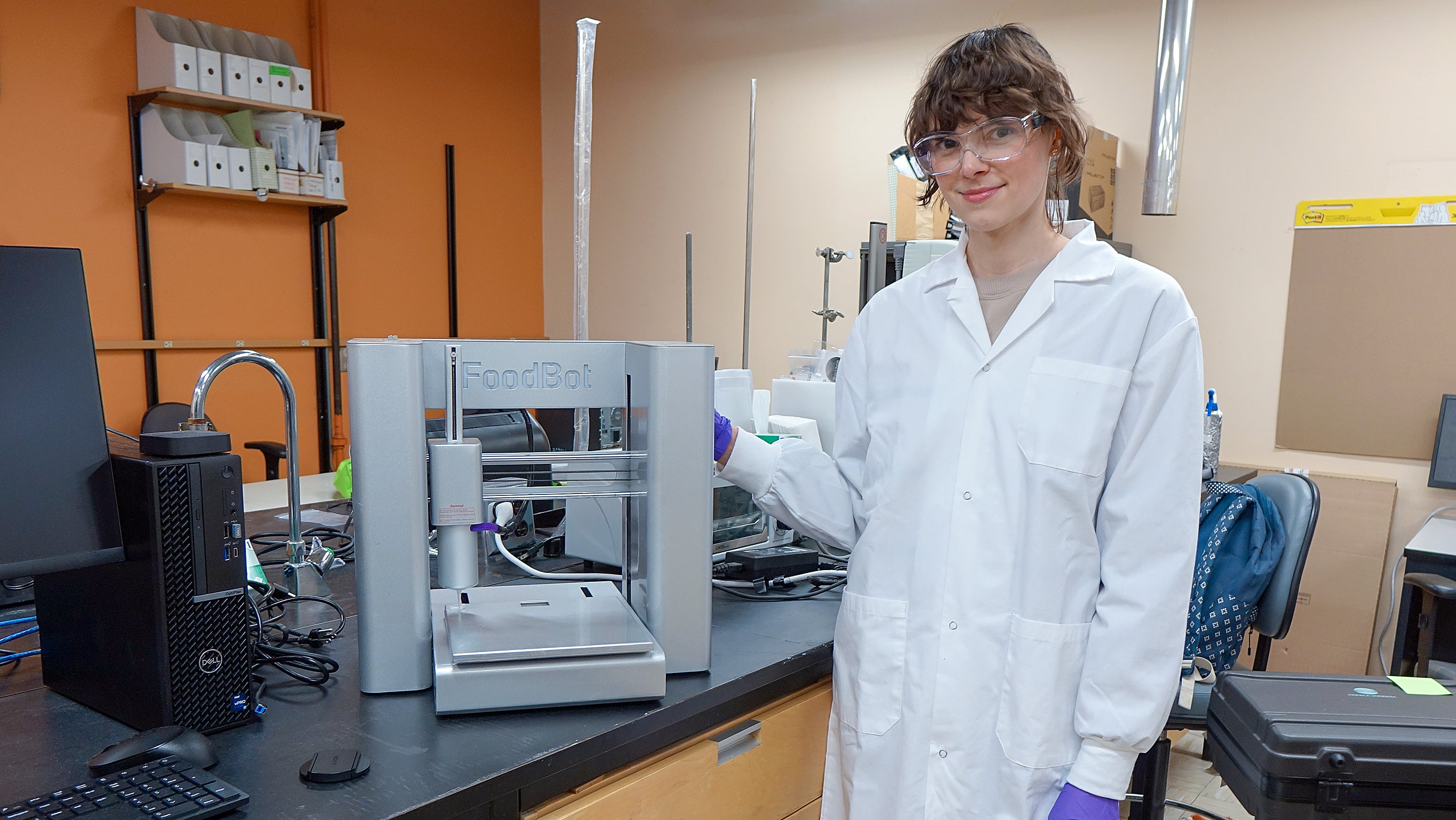

The research helps build knowledge about increasing food safety in the rapidly developing technology of 3D printing, says Julia Barsukova, who conducted the work to earn a master’s degree in bioresource technology from the Faculty of Agricultural, Life & Environmental Sciences.

“It shows that we can use the printer itself to create safe conditions,” she says. “The heating element is already there, and we know heat kills bacteria, so why not do that while printing food?”

Exploration of 3D printed foods using chocolate, sugar, dough, cheese, pudding, mashed potatoes and vegetable or fruit purées has grown over the past few years. The printing process creates foods with complex shapes, flavours and textures for everything from home and restaurant meals, to personalized diet plans for patients, athletes and even astronauts.

Most scientific research focuses on how the end product will look when it’s printed, notes Barsukova, who also holds a U of A bachelor of science in nutrition and food science.

“There are questions around whether it’s going to form a nice structure, whether it’s going to hold its shape, but the microbial safety aspect of 3D printed foods hasn’t been fully investigated.”

That’s important considering that many 3D printed foods, because they need to be pliable, contain ingredients with high levels of moisture, she adds.

“That could be problematic because high moisture levels can speed up bacterial growth if the food is contaminated.”

Usually created as ready-to-eat products, 3D printed edibles “can be contaminated like any other food,” Barsukova adds.

Unlike equipment used in food manufacturing facilities, 3D printers, which are currently marketed as a niche item largely used by startup businesses or at home, contain components that can’t be fully taken apart for easy cleaning.

“If there are microbial pathogens coming from the printer itself or somewhere in the production stage, you can get food poisoning,” she notes.

Her work, conducted in the U of A’s Food Safety and Sustainability Engineering Research lab, identified the most effective times and temperatures needed for the heating element in the printer, a small stainless steel barrel. Coated and heated by a thin plastic film, the barrel contains a syringe used to squeeze out the pliable food paste. The heated barrel warms the syringe through conduction, to keep the paste soft.

For her research, Barsukova contaminated pudding with Salmonella enterica serovar Typhimurium, a food-borne pathogen associated with recalls of high- and low-moisture foods.

Before and during printing, Barsukova heated the pudding inside the syringe at times and temperatures that would normally be needed to kill the bacteria. The time-temperature combinations she used ranged from 10 to 40 minutes and from 55 C to 66 C.

The inactivation of the bacteria increased with higher temperatures and heating times, with the greatest reduction happening when the barrel was heated for 40 minutes at temperatures of 63 C and 66 C.

Although these findings were expected, the experiments provide valuable confirmation that the heating element in the printer is indeed effective in killing harmful bacteria, Barsukova notes.

“By giving us the optimum time and temperatures to kill this particular strain of Salmonella that might be present in the food before or during the printing process, this work helps ensure the printed product is safe to consume.”

In her work, Barsukova also used numerical modelling to create heat maps within the pudding-filled syringe, which helped show cooler spots where bacteria wasn’t being adequately mitigated.

Such mathematical simulations can be “good additional tools for assuring safety in 3D food printing,” she notes.

The study represents a step toward increasing food safety when 3D printing is used, says professor M.S. Roopesh, who co-supervised Barsukova’s work with adjunct professor John Wolodko.

“We were able to see the effect of time-temperature combinations on the microbial safety of a 3D printed product, similar to what occurs during the pasteurization of dairy products or sterilization of canned products,” notes Roopesh, whose lab is also working on 3D printability improvement of plant proteins such as fava beans and peas, using novel techniques like plasma-activated water bubbles.

Having that type of information will be useful if 3D food printing reaches industrial-level production of ready-to-eat products, he suggests.

“While the concept needs further research, especially to understand the heat resistance of other microbial pathogens during 3D printing, ways to achieve more efficient, fast heating before and during the printing process could be factors companies target in the future.”

The research was funded as part of Wolodko’s former Alberta Innovates Strategic Chair in Bio and Industrial Materials.