Researchers at the University of Alberta have fine-tuned a process for creating accurate digital 3D reconstructions of human bones, offering students and researchers a cost-effective and accessible way to study anatomy and biomechanics.

The new process uses a technique called 3D photogrammetry, which involves photographing an object multiple times from various angles. The result is a lifelike digital representation of the object that can be manipulated virtually or 3D printed to create physical models.

“When the photograph was invented, it was this great thing because we could capture something at a moment in time. But it’s in two-dimensional space, and we live in a three-dimensional world. Being able to capture an object in 3D space allows us to better preserve that information,” says Loren Chiu, an associate professor in the Faculty of Kinesiology, Sport, and Recreation who led the research alongside graduate student Jasmine Feddema.

For their method, Chiu and Feddema placed a bone on a turntable and rotated it, taking photos to get a 360-degree view. They then flipped the bone upside down and repeated the process to generate the full 3D image. According to Chiu, their approach usually yields 60 to 100 photographs that are combined using software to create the digital reconstruction.

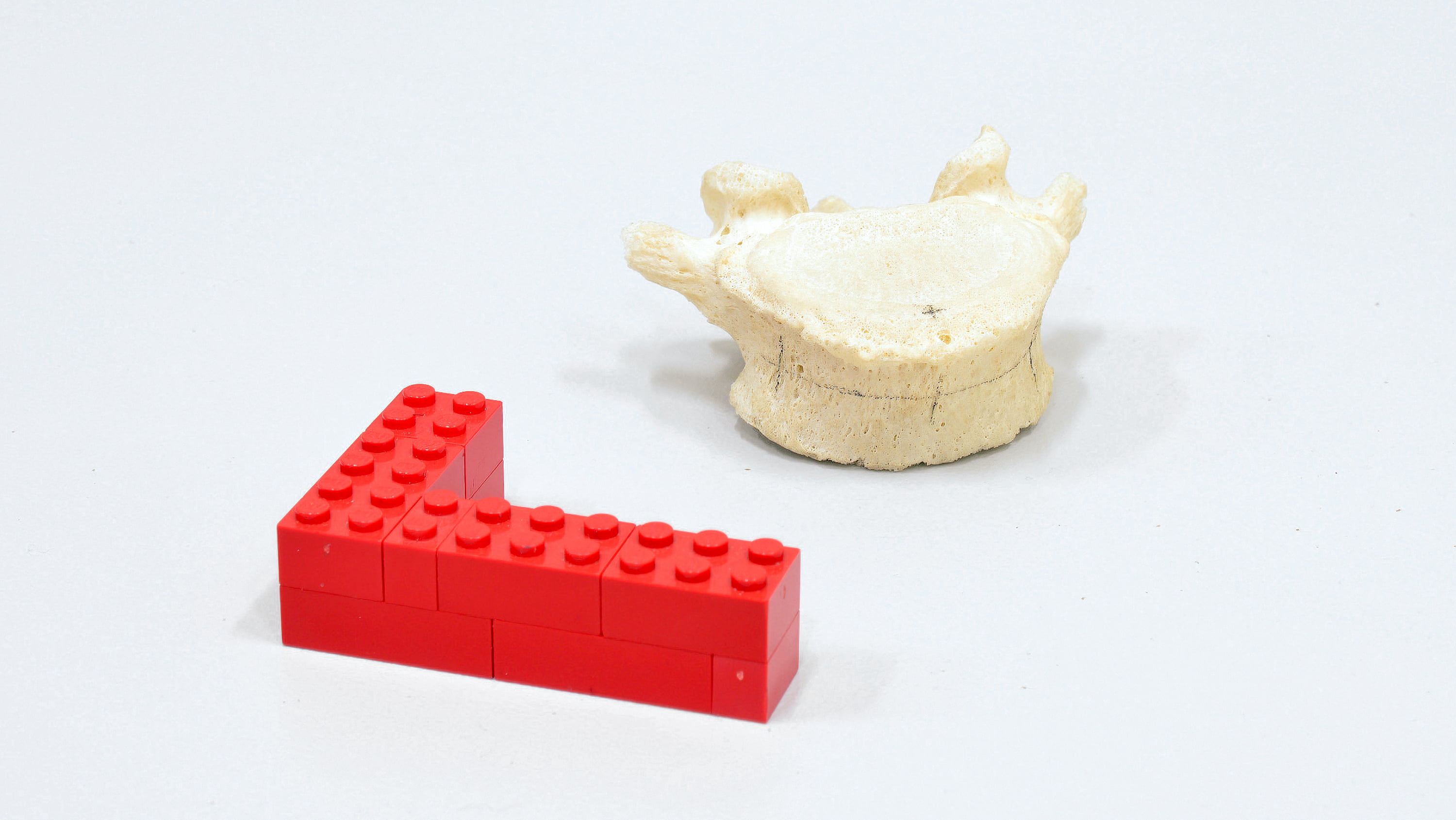

A comparison of their digital reconstructions with the five actual bones they photographed confirmed their approach produced accurate representations.

“Being able to reconstruct something and make sure it is very faithful to the original object we have is critical, otherwise the data we get aren’t going to be accurate and we can’t use that reconstruction for scientific study,” says Chiu.

They later repeated the entire process to verify that the approach laid out in their study was reproducible and the reconstructions remained consistent regardless of when the images were taken or who captured them.

“If everyone gets a different result, or you get different results on different days, it’s likely not good enough for us to use scientifically.”

Their 3D photogrammetry process requires only a standard digital camera and inexpensive software, making it possible for those with limited resources to create digital reconstructions. It also makes studying anatomy and biomechanics accessible for students at institutions that aren’t equipped with a cadaver lab.

“This kind of material can only be handled in specific labs that have biosafety protocols in place, so this is information that is not readily available to many people.”

3D photogrammetry also ensures objects can be preserved indefinitely. Some physical objects, like the bones Chiu and Feddema were reproducing, can significantly degrade over time. Digital reconstructions do not, ensuring any reproductions constructed will be available for future research and education. And 3D printed versions of those reproductions can be created at a quarter to a third of the cost of buying human bone reconstructions from suppliers, Chiu notes.

The reconstructions are valuable for anatomical education, Chiu says. Students can view and manipulate a detailed 3D model of the bones, allowing them to assess the bone from multiple angles on multiple devices. For biomechanics research, students and researchers can use the digital models to see how bones interact with muscles and ligaments during movement, providing insight into treating musculoskeletal conditions.

Chiu points out that students can also be involved in creating the reproductions — a hands-on learning opportunity that doesn’t exist with reproduction bones bought from a supplier.

The process Chiu and Feddema outlined can be applied to any type of object, making it useful in other fields. For example, since dinosaur bones can degrade the same way human bones do when exposed to dry or humid conditions, the technology offers an alternative to the time-consuming process of plaster-casting bones to create reproductions for display.

“We’ve moved so far ahead in our technology that if the best we can do is turn the textbook page into a PDF file, we’re underusing our capabilities,” Chiu says. “We could be at the forefront of using these types of technologies from an academic perspective, and that could be really beneficial for our research and what our students are able to contribute in the future.”